High-Tech, Productive and Affordable Atta Mixture Machine, Katori Chaat Machine, Samosa Patti Cutting Machine, etc.

Vishal Engg. Works has been a trusted name in the manufacturing and

supply of high-quality food processing machines in Ulhasnagar,

Maharashtra, India. Over the past decades, we have built a reputation

for excellence, reliability, and innovation, catering to the diverse

needs of small businesses, commercial kitchens, and large-scale food

processing units across India.

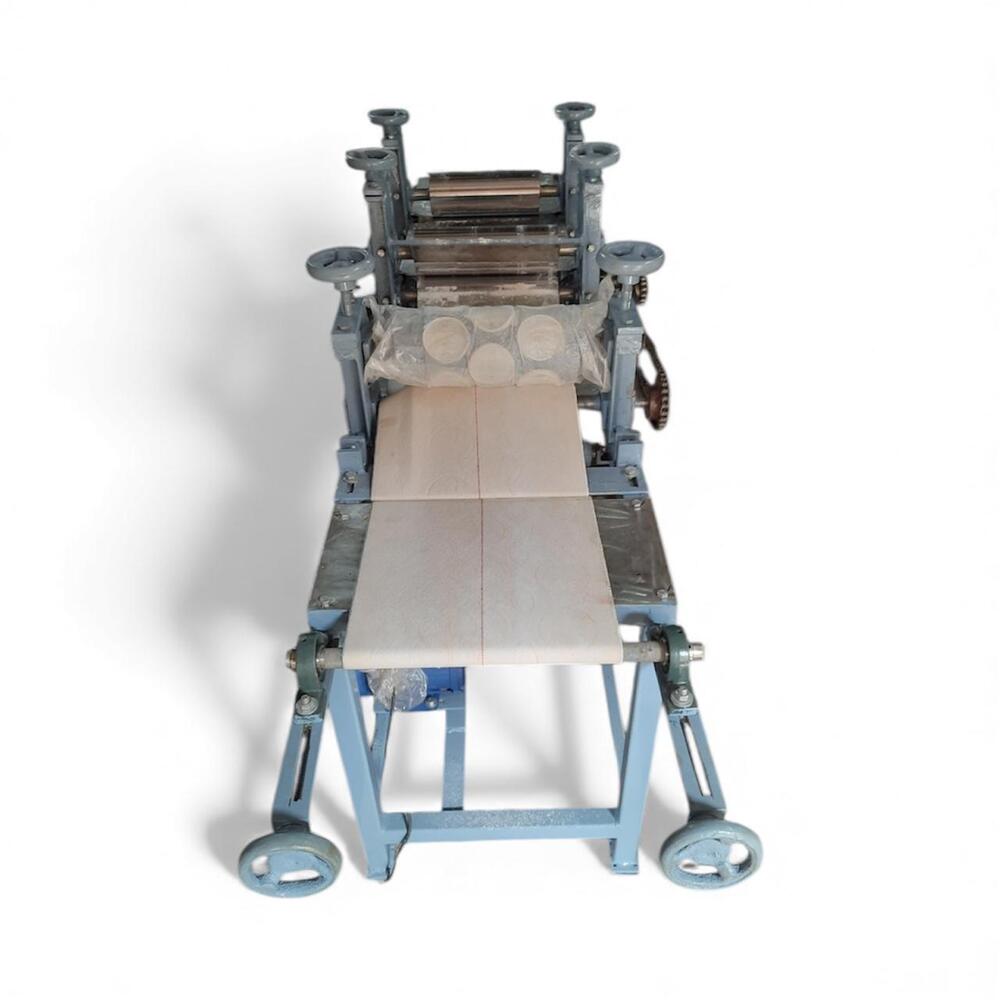

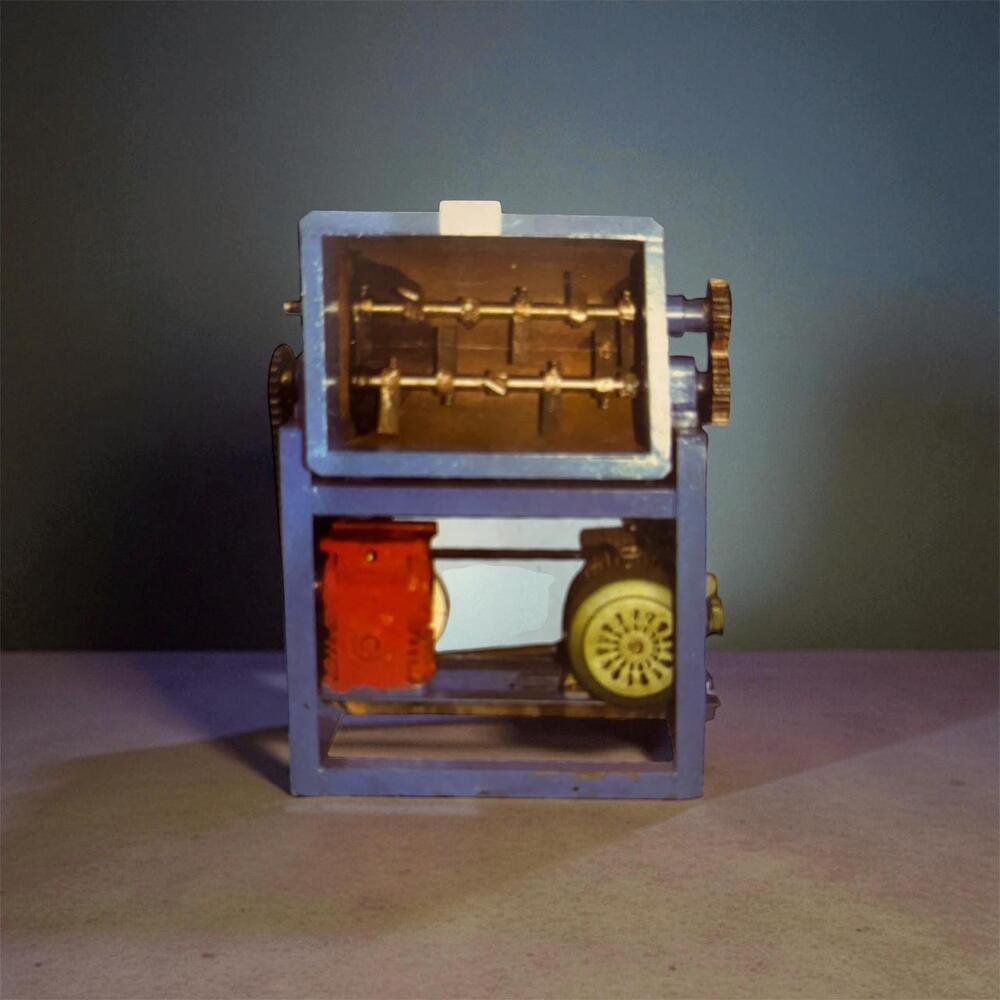

As a manufacturer and supplier, we specialize in designing and producing a wide range of food processing equipment, including the Atta Mixture Machine, Katori Chaat Machine, Samosa Patti Cutting Machine, and other custom machinery tailored to meet the specific requirements of our clients. Each of our products is crafted with precision, durability, and efficiency in mind, ensuring smooth operation, minimal maintenance, and optimal performance. Our machines are engineered using the latest technology and high-grade materials to provide long-lasting service, making them a preferred choice for both domestic and commercial use.

Our Expertise

At Vishal Engg. Works, we believe that quality products are only part of the solution; exceptional support and services are equally important. Our after-sales services are designed to provide comprehensive assistance to our customers, ensuring that their operations remain uninterrupted and productive. Our team of experienced professionals offers:

Our Production Facilities

At Vishal Engineering Works, our production facilities in Ulhasnagar, Maharashtra, are designed to deliver precision, efficiency, and high-quality output. Established in 1995, our manufacturing unit is equipped with modern machinery and advanced tools, enabling us to produce a wide range of food processing equipment such as Atta Mixture Machines, Katori Chaat Machines, Samosa Patti Cutting Machines, and more.

Our facility is organized to optimize every stage of production, from material sourcing to final assembly. Skilled engineers and technicians work closely to ensure that each machine meets stringent quality standards and is durable, reliable, and user-friendly. We maintain strict quality control at every step, ensuring that every product leaving our factory is of the highest standard.

In addition to manufacturing, our facilities also support comprehensive after-sales services. We have dedicated sections for installation, maintenance, repair, and commissioning, allowing us to provide complete support to our customers.

Our commitment to innovation and continuous improvement ensures that our production facilities remain up-to-date with the latest technologies and manufacturing practices. This allows Vishal Engineering Works to consistently deliver high-performance machinery that meets the evolving needs of the food processing industry.

Why Choose Vishal Engineering Works?

As a manufacturer and supplier, we specialize in designing and producing a wide range of food processing equipment, including the Atta Mixture Machine, Katori Chaat Machine, Samosa Patti Cutting Machine, and other custom machinery tailored to meet the specific requirements of our clients. Each of our products is crafted with precision, durability, and efficiency in mind, ensuring smooth operation, minimal maintenance, and optimal performance. Our machines are engineered using the latest technology and high-grade materials to provide long-lasting service, making them a preferred choice for both domestic and commercial use.

Our Expertise

At Vishal Engg. Works, we believe that quality products are only part of the solution; exceptional support and services are equally important. Our after-sales services are designed to provide comprehensive assistance to our customers, ensuring that their operations remain uninterrupted and productive. Our team of experienced professionals offers:

- Installation Services: We ensure that all machines are correctly installed at the clients premises, with proper alignment and calibration, so they operate at peak efficiency from day one.

- Maintenance Services: Regular maintenance is essential for prolonging the life of any machine. Our skilled technicians provide preventive maintenance checks and timely servicing to prevent any unexpected downtime.

- Repairing Services: In the event of a malfunction or breakdown, we provide quick and effective repair solutions, minimizing disruption and ensuring machines are restored to optimal working condition.

- Erection and Commissioning Services: We handle the complete setup of machinery, from initial erection to final commissioning, making certain that each machine operates seamlessly in its intended environment.

Our Production Facilities

At Vishal Engineering Works, our production facilities in Ulhasnagar, Maharashtra, are designed to deliver precision, efficiency, and high-quality output. Established in 1995, our manufacturing unit is equipped with modern machinery and advanced tools, enabling us to produce a wide range of food processing equipment such as Atta Mixture Machines, Katori Chaat Machines, Samosa Patti Cutting Machines, and more.

Our facility is organized to optimize every stage of production, from material sourcing to final assembly. Skilled engineers and technicians work closely to ensure that each machine meets stringent quality standards and is durable, reliable, and user-friendly. We maintain strict quality control at every step, ensuring that every product leaving our factory is of the highest standard.

In addition to manufacturing, our facilities also support comprehensive after-sales services. We have dedicated sections for installation, maintenance, repair, and commissioning, allowing us to provide complete support to our customers.

Our commitment to innovation and continuous improvement ensures that our production facilities remain up-to-date with the latest technologies and manufacturing practices. This allows Vishal Engineering Works to consistently deliver high-performance machinery that meets the evolving needs of the food processing industry.

Why Choose Vishal Engineering Works?

- High-quality, durable, and reliable machines designed for efficiency.

- Wide range of products, including Atta Mixture Machines, Katori Chaat Machines, Samosa Patti Cutting Machines, and more.

- State-of-the-art production facilities with skilled engineers and advanced machinery.

- Comprehensive after-sales support: installation, maintenance, repair, and commissioning services.

- Strict quality control at every stage to ensure consistent product excellence.

- Customer-focused approach with prompt and professional service.

- Commitment to innovation and adoption of the latest manufacturing technologies.

- Competitive pricing without compromising on quality.